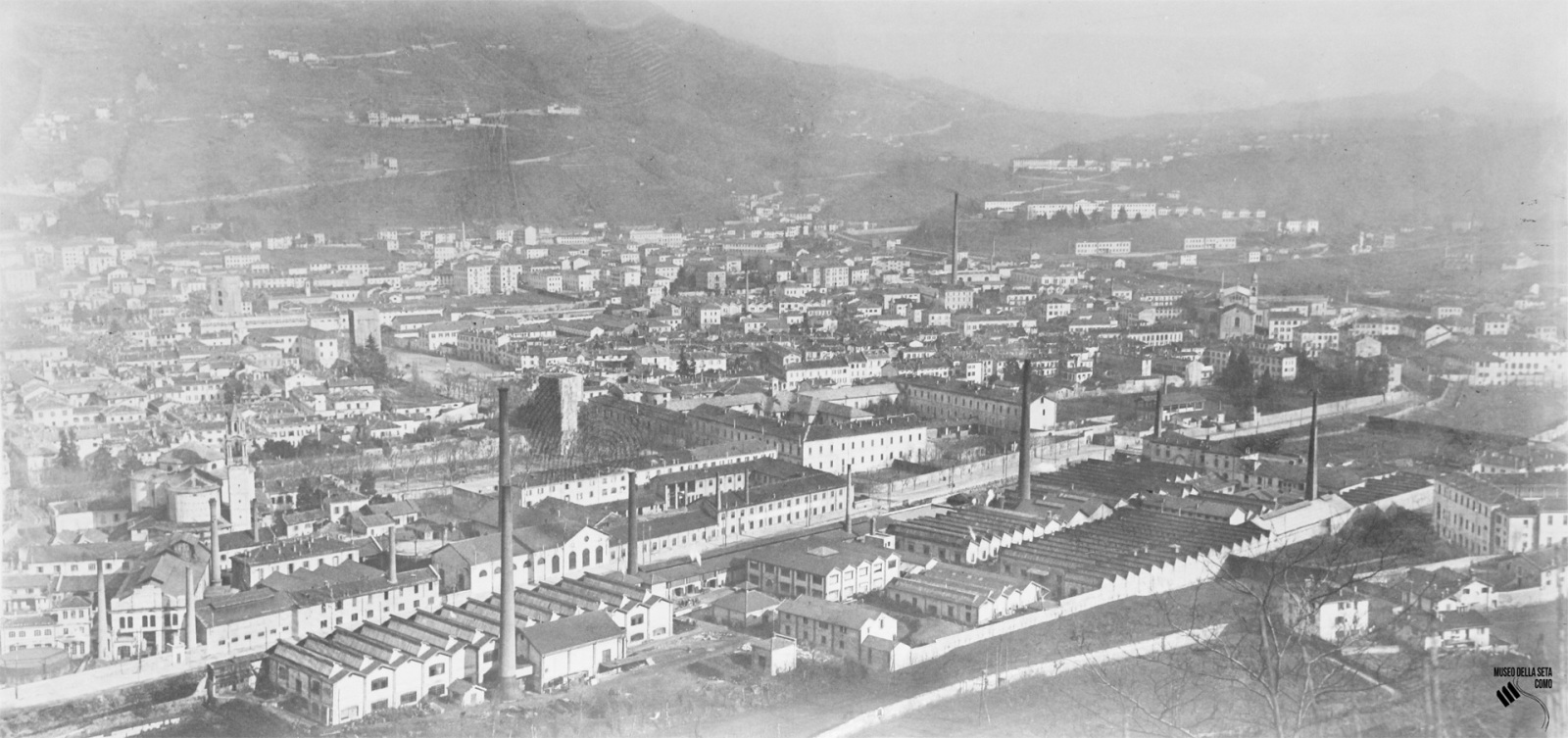

Once upon a time there was silk

Brief historical dictionary of silk in the age in which durability and sustainability were just lightly touched by the industry

The consequences of low durability and sustainability:

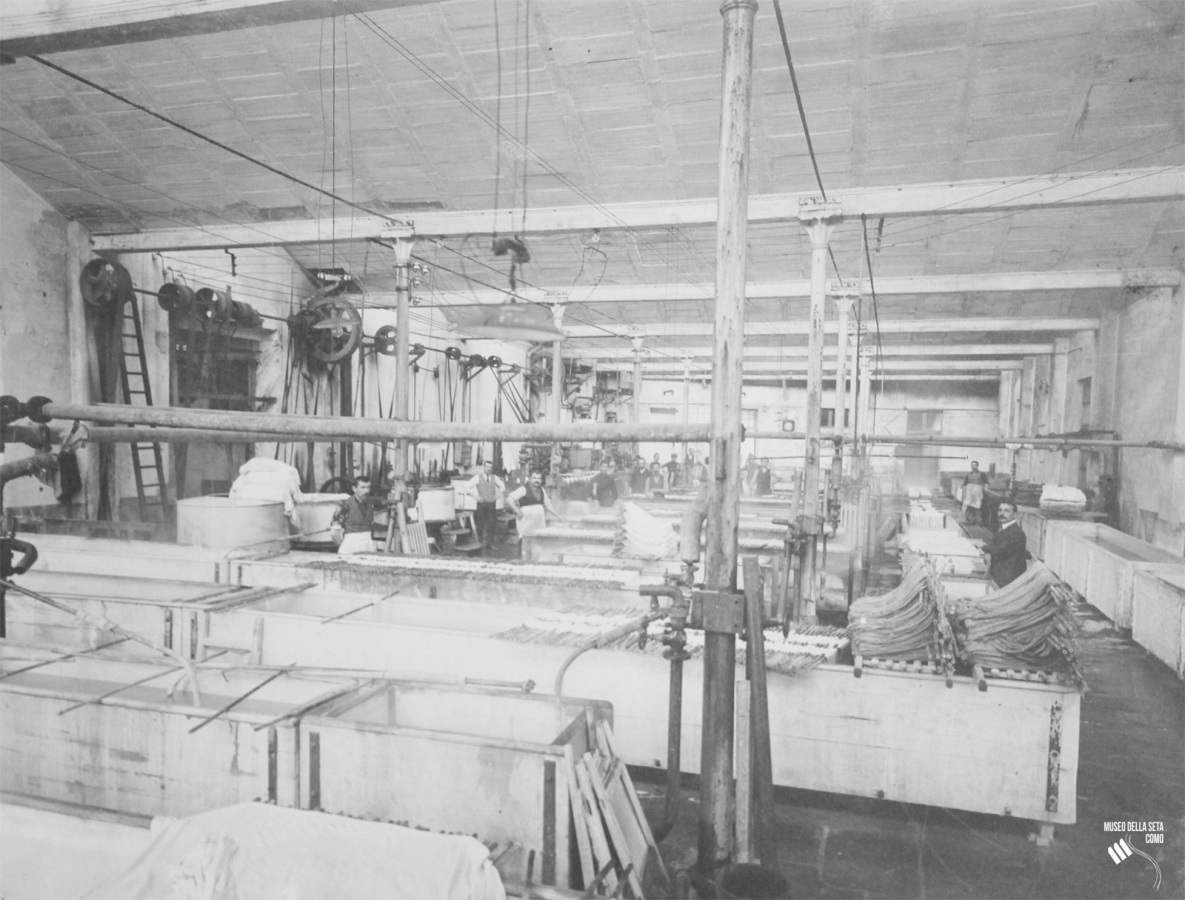

CHRONIC RESPIRATORY DISEASES

Due to a low durability and sustainability within the environment of the dyeing departments - mainly in those where the silk was purged - the atmosphere was constantly pervaded by heavy mists released by the appliances, at the time devoid of any form of coverage.

Especially during the winter season, this fog (known by the dialectal name of "baff") was also cold and therefore the cause of repeated bronchitis and pneumonia, which also tended to become chronic.

ANILINA AND THE WIDOW FACTORY

Aniline, a substance that has had a great responsibility in the history and development of organic chemistry applied to the world of textile dyes, has been recognized as highly carcinogenic and, like it, other aromatic amines (for example benzidine) have now been eliminated, so much so that their use for the manufacture of fabric dyes is now prohibited.

Emblematic was the case of the chemical companies that, until the second post-war period, used it to manufacture dyes in plants totally devoid of adequate individual protection tools. As an example, the IPCA of Ciriè (To) - Piedmontese Industry of Aniline Dyes - sadly known as the "Widows Factory", such was the mortality from bladder cancer of the employed workers.

The terrible characteristic of aniline decreases a lot when it is complexed in the dye molecules, so the fabrics (and the related garments made with them), even if dyed or printed with aniline dyes, can be used without particular danger.

Aniline dyes were sought after and appreciated for two reasons:

Con il contributo di

CHRONIC RESPIRATORY DISEASES

Due to a low durability and sustainability within the environment of the dyeing departments - mainly in those where the silk was purged - the atmosphere was constantly pervaded by heavy mists released by the appliances, at the time devoid of any form of coverage.

Especially during the winter season, this fog (known by the dialectal name of "baff") was also cold and therefore the cause of repeated bronchitis and pneumonia, which also tended to become chronic.

ANILINA AND THE WIDOW FACTORY

Aniline, a substance that has had a great responsibility in the history and development of organic chemistry applied to the world of textile dyes, has been recognized as highly carcinogenic and, like it, other aromatic amines (for example benzidine) have now been eliminated, so much so that their use for the manufacture of fabric dyes is now prohibited.

Emblematic was the case of the chemical companies that, until the second post-war period, used it to manufacture dyes in plants totally devoid of adequate individual protection tools. As an example, the IPCA of Ciriè (To) - Piedmontese Industry of Aniline Dyes - sadly known as the "Widows Factory", such was the mortality from bladder cancer of the employed workers.

The terrible characteristic of aniline decreases a lot when it is complexed in the dye molecules, so the fabrics (and the related garments made with them), even if dyed or printed with aniline dyes, can be used without particular danger.

Aniline dyes were sought after and appreciated for two reasons:

- the low cost, both of the raw material and of the ease of preparation

- the fact that these dyes are easily destroyed by reducing agents

This is an important quality within the Como textile industry, which has always used them to prepare dyed undercoats to be printed in corrosion, processing and has always been the pride of the Como silk industry. The problem arises from the fact that, during this process - which develops during the vaporization phase - aniline is restored among the dye demolition products which, as an aerosol, ends up in the atmosphere of the departments, with harmful consequences.

DEFORMING ARTHRITIS

It was the typical pathological affection of the hands of spinners, always in contact with the hot water of the reeling trays. To mitigate and withstand the strong heat of the bowls, the women had a tub of cold water available to refresh their hands. Over time, the fingers remained deformed and sore due to severe forms of arthritis, known as “basin ache”. The recommended cure was to use your own urine as a soothing agent.

BOILERS ... SHELL

Those were the times of the Second World War, a time of self-sufficiency and difficult supply of raw materials, including fuels. The boilers were then coal-fired, but coal was in short supply. In Tintoria Pessina they worked hard and, in order not to slow down with work, they used the shells and kernels of oil seeds, residual waste from the squeezing, as an alternative fuel.

In temp de guèra, i caldér andavan cônt i güss di giand armandôl! (In times of war the boilers worked with almond gas): this is what the workers used to say, in dialect.

Perhaps it was one of the first forms of ecological recovery ante litteram, because those wastes would inevitably be destined only for the landfill.

FORMALIN, FORMALDEHYDE OR ANT ALDEHYDE

The danger of harmfulness was not confined only to aniline and the like: even the naphthol dyes had just as much toxicity. To tell the truth, in the Como area this category of dyes was little used, so the related carcinogenic risk problems were very limited.

Also, among the various other products used in the dyeing industry there were real monsters of danger and, among these, the formaldehyde excelled that has finally been recognized as a substance with high toxicity and certainly carcinogenic agent ending up blacklisted.

This was used in dyeing to improve the wet fastness of black tones on silk but, much more massively, to prepare in situ the anti-crease resins used above all in the finishing of viscose fabrics.

First, a mixture of urea with formaldehyde was extemporaneously prepared, put in excess, "so much (it was said) it is volatile and during application the excess evaporates and goes away": the dyers of the time still remember the characteristic tingling in the throat and burning eyes when the treatment was done. In the golden years of the processing of heavy viscose fabrics, it was necessary to prepare the anti-crease several times a day and this gives the measure of how much formaldehyde went around the finishing departments.

Today finally, pre-condensed urea (or melamine) and formaldehyde are used in an almost stoichiometric ratio, which is why there is no longer the presence of free formaldehyde, either in the environments or on the fabrics (which is no longer tolerated by current regulations). And to think that, as a child in the 50-60s when you had a sore throat, the pharmacist prescribed Formitrol tablets "with active formaldehyde".

POLLUTION BY HEXAVALENT CHROME AND OTHER HEAVY METALS

Before the advent of new categories of dyes with high fastness that allow excellent resistance to fulling of the wool, chromium dyes were commonly used in which the metal (in the form of hexavalent chromium salts) acts as a complexing agent for the dye. already climbed on the fiber forming a strongly insoluble lacquer.

The fixation was carried out by treating the dyed goods with a potassium dichromate bath; bathroom which, at the end, was discharged directly into the waste water, with its load of heavy metal that heavily polluted the aquifers.

Even when the purification plants came into operation, things were no better, because the hexavalent chromium was able to put them out of use, as it was toxic to the microorganisms responsible for digesting wastewater.

If the problem was strongly felt in the wool districts, even Como was not safe from this pitfall because in our district this type of dyes was used (also if in much smaller quantities) for the black dyeing of elastic fabrics for women's corsetry.

In Como, potassium permanganate was usually used in the printing works to clean those white backgrounds of printed swimwear fabrics that were influenced by color during the post-printing washing phase. Also, in this case the toilets were quietly discharged into the lake.

LANDSCAPE REMODELED

The peat bog of Albate is a humid area barred by a short moraine cordon where a slight depression has been created and where, among other things, the waters coming from the Basca Valley converge.

Over time, the stagnation of water created a large area covered with peat. The Tintoria Pessina obtained the concession to take peat for fuel use and began to excavate and remove the surface peat layer.

The extraction activity, from the mid-thirties, continued until the postwar period without interruption.

The quality of the fuel obtained was very poor, as the peat is soaked in water and needs a long drying time before it can be used, without forgetting that its calorific value is really low, but it has become a virtue of necessity.

The excavation area, at the end of the sampling, turned out to be very large and, progressively, in the depression that was created two small lakes were formed, which have now become a precious refuge and resting place for sedentary and migratory waterfowl, so much so that the area has been declared of wildlife and environmental interest, obtaining the WWF blazon with the name of Oasi del Bassone.

Of course, it would have been better if a nefarious war had not broken out but, at least today, the Bassone is an oasis of peace!

RESOURCES FROM WASTE

It was customary for the dry cleaners who worked on behalf of third parties to keep a sample of the processed goods for possible disputes, should complaints arise for non-compliance or manufacturing defects.

Once the terms for any complaints expired, the fabric stretches were divided by type and so was for the processing scraps.

The silk was sold directly to the cascamificio (the kind of company that processes usable residues from the processing of another product), to re-enter the cycle as schappe (reusable residue), and the traces of other fibers went to the ragmen of Prato who divided them and transformed them into "new" yarns and fabrics.

This was at least until the wading factory was in operation and the fibers worked were natural and / or artificial ones. The advent of synthetic fibers and their blends has made the separation of the fibers more complicated, difficult and uneconomical, and therefore also the recovery of waste in view of their reuse.

Another destination was the waste of the yarns in the Pessina dyeing house.

The scraps and the expired references made of silk were sold untouched to the cascamificio (as for the fabric scraps).

In this ingenious way, the references of yarns of other nature found new life: using a braiding machine they were coupled and transformed into variously colored cords and used as twine to tie the bundles of skeins to be sent to customers.

The plaiting machine was placed in a room adjacent to the porter's lodge and was put into operation by the night guard: the noise was such as to effectively help keep the vigilante awake.

SATURNISM

The polishers used lead black ink to make the transparencies used to prepare the printing pictures. It was a particular ink in which the lead component contributed to a greater impenetrability to light, to obtain sharper and better-defined photoengraving in minute details.

As is customary, to obtain very fine and subtle details in painting it is necessary to thin the tip of the brush, which painters usually achieve by squeezing the apex of the tips between lips moistened with saliva. Over time, the lead in the ink was absorbed by the body through the digestive system, leading to sometimes severe cases of saturnism (Nausea, vomiting, diarrhea, intense abdominal pain, anemia, jaundice, kidney failure)

DEAFNESS

In the weaving departments, when the looms worked with the shuttles, the continuous and repeated sharp blow inflicted by the swords on the shuttle produced a deafening noise that inevitably generated deafness. Now shuttle looms are almost a thing of the past and the new weft insertion technologies are much less noisy; in addition, protective headphones were also introduced, so today the hearing of the weavers has benefited greatly.

TIN: WASTEWATER AND SILK CHARGE

At least one third of the tin which was used in the processes of mineral loading of silk was lost in the washing waters.

To tell the truth, the tin that flowed freely into Lake Como was not particularly dangerous, as tin is a heavy non-toxic metal (just think of the tinplate of cans used before the enameled strip).

The boys of the early twentieth century generation went to make the slide on the big mud (scivolo sül paltôn, in dialect) referring to the slippery sediment formed by the accumulation of tin hydrates on the mouth of the free discharge of the waste water of the Tintoria Pessina in Cosia.

The recovery of tin was born as a response to an economic problem, given the high value that this metal has always had.

On the other hand, until the 1970s, no one was concerned with ecology and environmental sustainability; indeed, it was considered only an avoidable cost.

Paolo Aquilini

Direttore del Museo della Seta di Como

DEFORMING ARTHRITIS

It was the typical pathological affection of the hands of spinners, always in contact with the hot water of the reeling trays. To mitigate and withstand the strong heat of the bowls, the women had a tub of cold water available to refresh their hands. Over time, the fingers remained deformed and sore due to severe forms of arthritis, known as “basin ache”. The recommended cure was to use your own urine as a soothing agent.

BOILERS ... SHELL

Those were the times of the Second World War, a time of self-sufficiency and difficult supply of raw materials, including fuels. The boilers were then coal-fired, but coal was in short supply. In Tintoria Pessina they worked hard and, in order not to slow down with work, they used the shells and kernels of oil seeds, residual waste from the squeezing, as an alternative fuel.

In temp de guèra, i caldér andavan cônt i güss di giand armandôl! (In times of war the boilers worked with almond gas): this is what the workers used to say, in dialect.

Perhaps it was one of the first forms of ecological recovery ante litteram, because those wastes would inevitably be destined only for the landfill.

FORMALIN, FORMALDEHYDE OR ANT ALDEHYDE

The danger of harmfulness was not confined only to aniline and the like: even the naphthol dyes had just as much toxicity. To tell the truth, in the Como area this category of dyes was little used, so the related carcinogenic risk problems were very limited.

Also, among the various other products used in the dyeing industry there were real monsters of danger and, among these, the formaldehyde excelled that has finally been recognized as a substance with high toxicity and certainly carcinogenic agent ending up blacklisted.

This was used in dyeing to improve the wet fastness of black tones on silk but, much more massively, to prepare in situ the anti-crease resins used above all in the finishing of viscose fabrics.

First, a mixture of urea with formaldehyde was extemporaneously prepared, put in excess, "so much (it was said) it is volatile and during application the excess evaporates and goes away": the dyers of the time still remember the characteristic tingling in the throat and burning eyes when the treatment was done. In the golden years of the processing of heavy viscose fabrics, it was necessary to prepare the anti-crease several times a day and this gives the measure of how much formaldehyde went around the finishing departments.

Today finally, pre-condensed urea (or melamine) and formaldehyde are used in an almost stoichiometric ratio, which is why there is no longer the presence of free formaldehyde, either in the environments or on the fabrics (which is no longer tolerated by current regulations). And to think that, as a child in the 50-60s when you had a sore throat, the pharmacist prescribed Formitrol tablets "with active formaldehyde".

POLLUTION BY HEXAVALENT CHROME AND OTHER HEAVY METALS

Before the advent of new categories of dyes with high fastness that allow excellent resistance to fulling of the wool, chromium dyes were commonly used in which the metal (in the form of hexavalent chromium salts) acts as a complexing agent for the dye. already climbed on the fiber forming a strongly insoluble lacquer.

The fixation was carried out by treating the dyed goods with a potassium dichromate bath; bathroom which, at the end, was discharged directly into the waste water, with its load of heavy metal that heavily polluted the aquifers.

Even when the purification plants came into operation, things were no better, because the hexavalent chromium was able to put them out of use, as it was toxic to the microorganisms responsible for digesting wastewater.

If the problem was strongly felt in the wool districts, even Como was not safe from this pitfall because in our district this type of dyes was used (also if in much smaller quantities) for the black dyeing of elastic fabrics for women's corsetry.

In Como, potassium permanganate was usually used in the printing works to clean those white backgrounds of printed swimwear fabrics that were influenced by color during the post-printing washing phase. Also, in this case the toilets were quietly discharged into the lake.

LANDSCAPE REMODELED

The peat bog of Albate is a humid area barred by a short moraine cordon where a slight depression has been created and where, among other things, the waters coming from the Basca Valley converge.

Over time, the stagnation of water created a large area covered with peat. The Tintoria Pessina obtained the concession to take peat for fuel use and began to excavate and remove the surface peat layer.

The extraction activity, from the mid-thirties, continued until the postwar period without interruption.

The quality of the fuel obtained was very poor, as the peat is soaked in water and needs a long drying time before it can be used, without forgetting that its calorific value is really low, but it has become a virtue of necessity.

The excavation area, at the end of the sampling, turned out to be very large and, progressively, in the depression that was created two small lakes were formed, which have now become a precious refuge and resting place for sedentary and migratory waterfowl, so much so that the area has been declared of wildlife and environmental interest, obtaining the WWF blazon with the name of Oasi del Bassone.

Of course, it would have been better if a nefarious war had not broken out but, at least today, the Bassone is an oasis of peace!

RESOURCES FROM WASTE

It was customary for the dry cleaners who worked on behalf of third parties to keep a sample of the processed goods for possible disputes, should complaints arise for non-compliance or manufacturing defects.

Once the terms for any complaints expired, the fabric stretches were divided by type and so was for the processing scraps.

The silk was sold directly to the cascamificio (the kind of company that processes usable residues from the processing of another product), to re-enter the cycle as schappe (reusable residue), and the traces of other fibers went to the ragmen of Prato who divided them and transformed them into "new" yarns and fabrics.

This was at least until the wading factory was in operation and the fibers worked were natural and / or artificial ones. The advent of synthetic fibers and their blends has made the separation of the fibers more complicated, difficult and uneconomical, and therefore also the recovery of waste in view of their reuse.

Another destination was the waste of the yarns in the Pessina dyeing house.

The scraps and the expired references made of silk were sold untouched to the cascamificio (as for the fabric scraps).

In this ingenious way, the references of yarns of other nature found new life: using a braiding machine they were coupled and transformed into variously colored cords and used as twine to tie the bundles of skeins to be sent to customers.

The plaiting machine was placed in a room adjacent to the porter's lodge and was put into operation by the night guard: the noise was such as to effectively help keep the vigilante awake.

SATURNISM

The polishers used lead black ink to make the transparencies used to prepare the printing pictures. It was a particular ink in which the lead component contributed to a greater impenetrability to light, to obtain sharper and better-defined photoengraving in minute details.

As is customary, to obtain very fine and subtle details in painting it is necessary to thin the tip of the brush, which painters usually achieve by squeezing the apex of the tips between lips moistened with saliva. Over time, the lead in the ink was absorbed by the body through the digestive system, leading to sometimes severe cases of saturnism (Nausea, vomiting, diarrhea, intense abdominal pain, anemia, jaundice, kidney failure)

DEAFNESS

In the weaving departments, when the looms worked with the shuttles, the continuous and repeated sharp blow inflicted by the swords on the shuttle produced a deafening noise that inevitably generated deafness. Now shuttle looms are almost a thing of the past and the new weft insertion technologies are much less noisy; in addition, protective headphones were also introduced, so today the hearing of the weavers has benefited greatly.

TIN: WASTEWATER AND SILK CHARGE

At least one third of the tin which was used in the processes of mineral loading of silk was lost in the washing waters.

To tell the truth, the tin that flowed freely into Lake Como was not particularly dangerous, as tin is a heavy non-toxic metal (just think of the tinplate of cans used before the enameled strip).

The boys of the early twentieth century generation went to make the slide on the big mud (scivolo sül paltôn, in dialect) referring to the slippery sediment formed by the accumulation of tin hydrates on the mouth of the free discharge of the waste water of the Tintoria Pessina in Cosia.

The recovery of tin was born as a response to an economic problem, given the high value that this metal has always had.

On the other hand, until the 1970s, no one was concerned with ecology and environmental sustainability; indeed, it was considered only an avoidable cost.

Paolo Aquilini

Direttore del Museo della Seta di Como

Con il contributo di

Come and visit us